Fabrics, upholstery for furnishing accessories, clothing as well as wooden surfaces and flooring can wear out and get ruined over time.

For manufacturers it is very important to evaluate the resistance of the product in advance, in order to ensure the final consumer a finished product of durability and quality.

Is it possible to assess these requirements?

Abrasion resistance is one of the most important tests not only for the evaluation of the performance of fabrics and coatings but also for the verification of the regulatory requirements for wooden surfaces of furniture, parquet and laminate flooring.

For the determination of abrasion resistance, one of the best known test methods is the “Martindale” abrasion test, the name of which derives from the equipment used.

The wood tests carried out with Martindale are mainly intended to determine the resistance of the surfaces to micrographs, exposing them to impact with the abrasive material for a certain number of rubbing; In this way, potential changes in the state of the surface are detected by visual examination or measurement of residual brilliance.

If we take the example of flooring, the Martindale test allows to obtain important information about the resistance of the surface treatment to wear; the test recreates a situation similar to what could happen due to the wear and tear caused by the time of use and the rubbing caused by the man who walks and lives inside the inhabited space.

Thanks to Martindale, COSMOB Testing Laboratory Division is able to meet different types of needs; tests applicable to furniture, laminates and laminate floors are mainly aimed at determining resistance to micrographs.

The main test methods are as follows:

- UNI CEN/TS 16611:2016 – Furniture – Evaluation of surface resistance to micrograffs.

- UNI EN 16094:2021 – Laminate floor coverings – Method for the determination of resistance to micrograffs.

- UNI EN 438-2:2019 – High pressure decorative laminates (HPL) – Sheets based on thermosetting resins (generally called laminates) – Part 2: Determination of properties- (Par. 30 – Determination of resistance to micrographs).

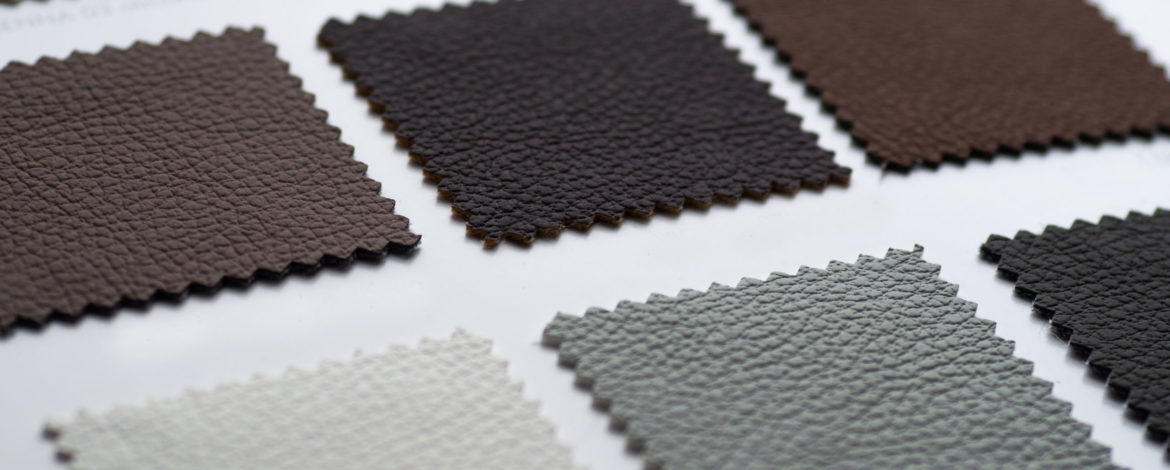

In addition, the Martindale is also used to analyze the resistance of fabrics and leathers to wear: in this case the aspects that are analyzed concern the resistance to breakage, pilling, in addition to potential color changes that may occur as a result of prolonged use over time.

In the textile sector, among the main international standards are the UNI EN ISO 12945-2:2021 Textiles – Determination of the propensity in textiles to the formation of pellets (pilling) hairiness (fuzzing) and rustling (matting) surface – Part 2: Modified Martindale Method and UNI EN ISO 12947-1:2000 Textiles – Determination of abrasion resistance of fabrics with the Martindale Method – Martindale equipment for abrasion testing.

Therefore, these tests are fundamental both in the design of a new textile or furniture product and to monitor the production, as they allow to select the most suitable raw materials for the specific application and to optimize the performance of the product ensuring its reliability over time.

Using tests to design and monitor product performance will allow companies to market safe, quality and competitive products in international markets.

For information:

Dott.ssa Ainara Melus Regidor

Chemical Department Technician – Quality Test Laboratory

a.melus@cosmob.it